Wide-format Printing: Maximizing POP displays with computerized cutting and routing

by all | 15 July 2015 9:29 am

[1]

[1]Photos courtesy Esko

By Stephen Bennett

It is no surprise many print service providers (PSPs) have been joining the wide-format graphics industry in recent years. Global sales of ink and media have experienced a compound annual growth rate (CAGR) of two per cent, reaching $3 billion and $29 billion, respectively, for a total of $32 billion; but the sellable output created with them has seen a CAGR of four per cent, reaching $42 billion. Compared to other print sectors, these are very attractive profit margins. And with growth in revenue continuing to outpace growth in costs of goods sold, the wide-format industry is clearly healthy.

The question is how PSPs will be able to charge more for sellable output in a changing market. At the moment, the broad range of viable options for digitally printed output includes signs, displays, packaging, collateral, labels and direct mail. It is important to understand how these various forms of printed output relate to consumers’ purchasing decisions.

Most outdoor signs, along with direct mail and printed collateral, typically contribute to exposure, motivation and recognition of the need for an advertised product. Research has demonstrated these aspects fuel 30 per cent of purchasing decisions.

The other 70 per cent of such decisions, however, are made at the point-of-purchase (POP), where retail displays, packaging and labels take on an elevated value for brand marketers. A recent survey conducted by the Path to Purchase Institute (P2PI) interviewed brand owners and found more than half of them responding with plans to put a greater emphasis on POP displays.

According to IT Strategies, a consultancy serving the digital print vendor community, POP and other in-store displays represent 70 to 80 per cent of demand among brand owners, while promotional packaging represents 15 to 25 per cent. The displays, whether two-dimensional (2-D) or three-dimensional (3-D), are typically made using corrugated or foam board and printed in medium- length runs averaging 300 pieces per job. The packaging, meanwhile, also uses corrugated board in 3-D configurations and commonly involves anywhere from one to 500 pieces per job. Demand for both applications is growing.

[2]

[2]Graphic design software can be used to set up templates for a variety of POP and merchandising formats.

IT Strategies estimates $17 billion is now spent annually on POP applications, trending toward digital printers because they can more efficiently handle variable run lengths than analogue technologies could. Customers include mass retailers (40 per cent), brand owners (40 per cent), other ‘retailers’ like restaurants, hotels, movie theatres and museums (10 per cent) and advertising, marketing, promotional and public relations (PR) agencies (10 per cent).

Unsurprisingly, all major large-format digital printer vendors are targeting the packaging and POP markets with their production presses. The increased availability of white and metallic inks, for example, is in large part a response to the use of non-white substrates for packaging applications.

Similarly, in recent years, computer numerical control (CNC) cutters and routers have helped graphics producers automate their finishing processes. With these digital systems, it has become more economically feasible to produce complex shapes, differentiate short runs and add value to end products.

Avoiding pricing challenges

Within this context, however, there are certain challenges to be faced. One is turnaround—given current customer expectations of digital workflows, some 70 per cent of jobs need to be completed in two days or less (compared to 10 days in 1997). Another is pricing, which has become highly competitive for graphics based on square footage of printing.

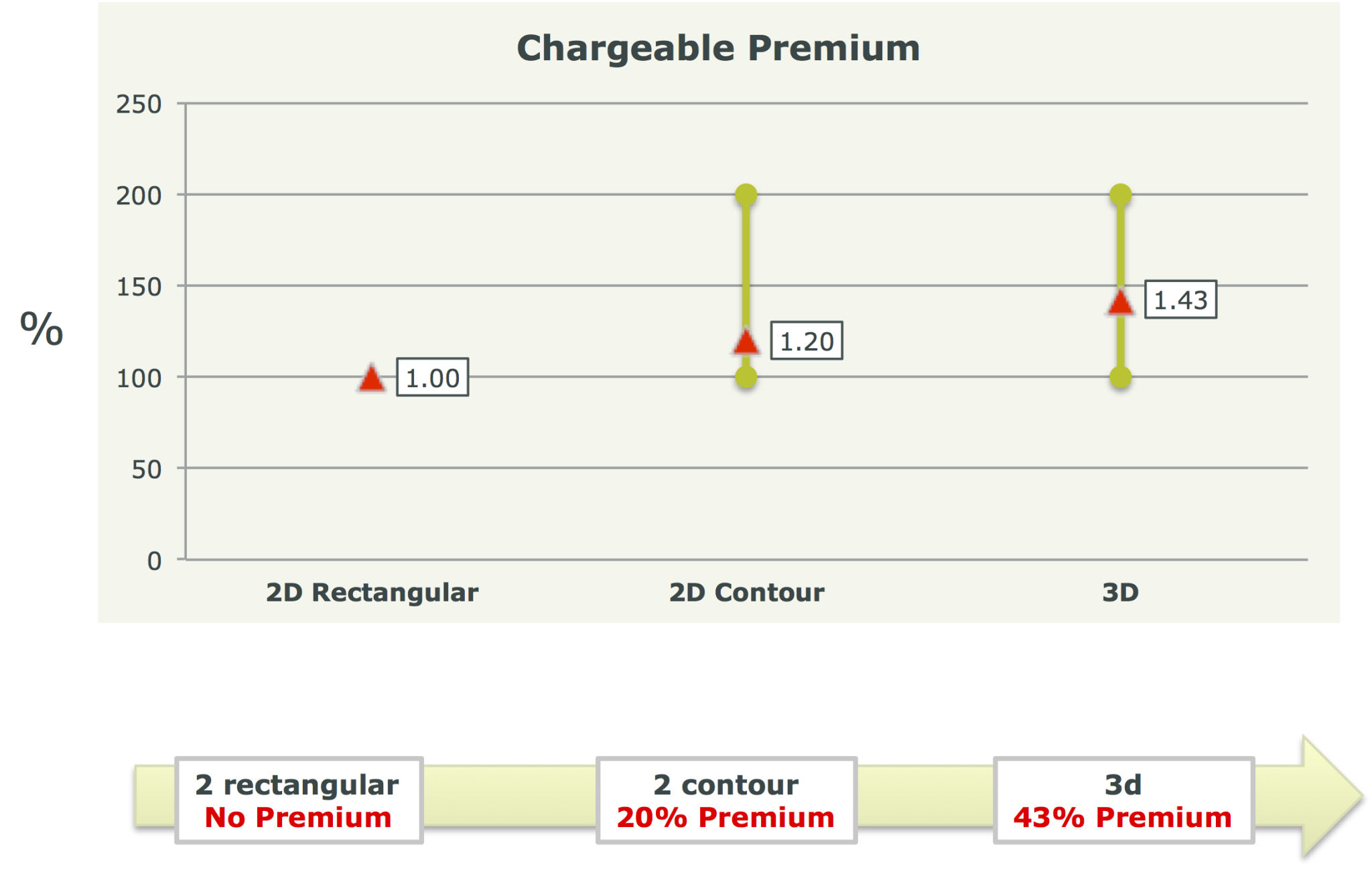

The answer to these challenges is to get out of square footage pricing and instead charge by the unit. In particular, additional value is attributed to POP displays that exceed 2-D rectangular formats (see Figure 1). For the same amount of effort, a contour-cut 2-D display in a unique shape can earn, on average, a 20 per cent premium, while a 3-D display can command a 43 per cent premium. This is not only because they require greater design considerations, but also because they are more impactful within retail environments.

[3]

[3]Figure 1

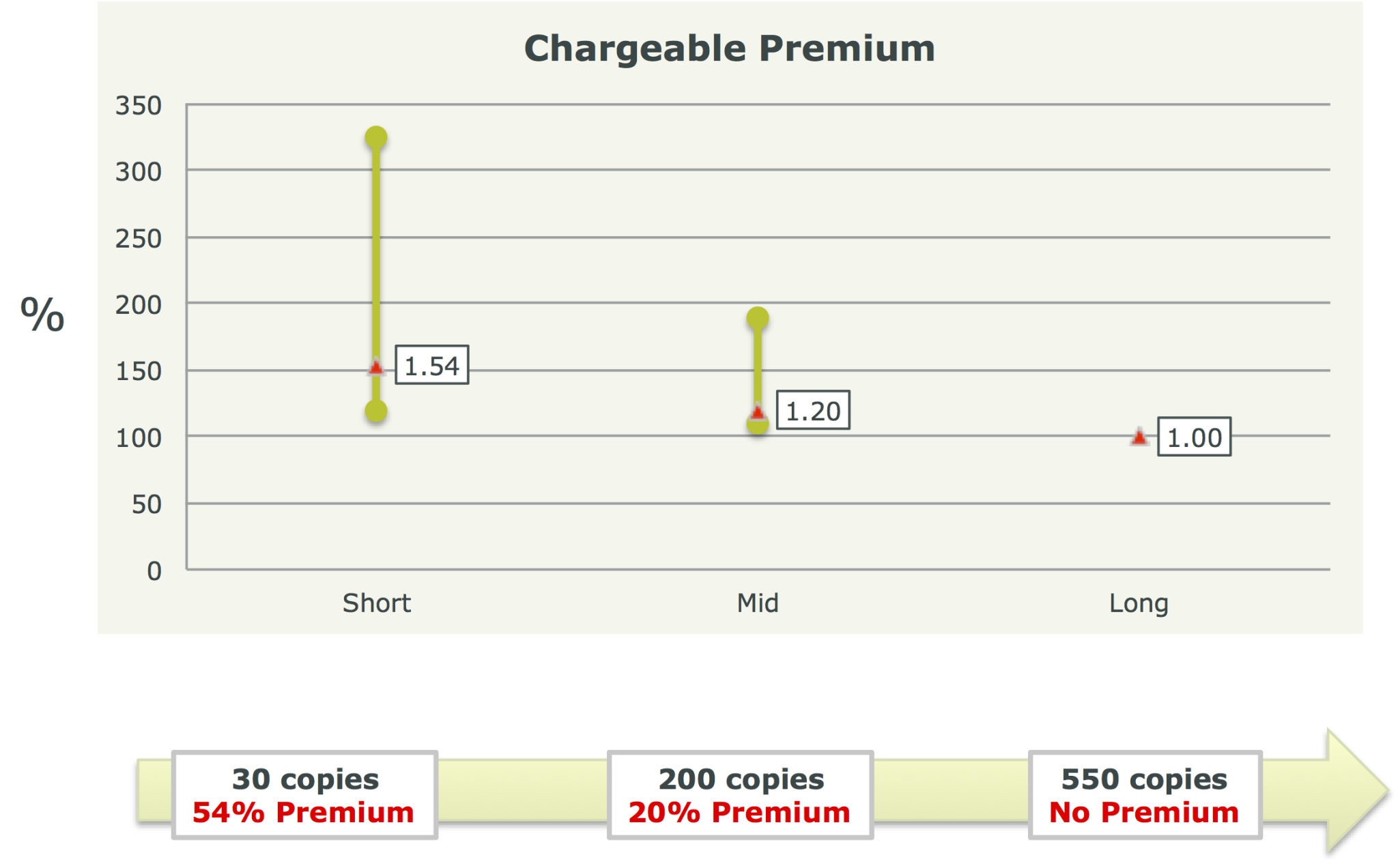

Further, short-run jobs can earn more of a premium than long-run jobs (see Figure 2). This is because sign shops can charge ‘on demand’ prices, with examples ranging from no premium for a 550-piece run to a 20 per cent premium for a 200-piece run and a 54 per cent premium for a 50-piece run.

As a result, the premiums a print shop can charge based on the complexity of a job are significant. From a rectangular to contoured shape, it is possible to triple net margins; and from a rectangle to a 3-D display, the increase is five to eight times. Further, by offering creative design services in-house, shops can enjoy net margins as much as 30 times typical ‘rectangular shape’ pricing, as those services involve not only graphic design, but also structural design, testing for integrity and other responsibilities.

[4]

[4]Figure 2

Building a new workflow

Taking advantage of such extraordinary business opportunities involves a broader skill set than simply printing the aforementioned inks on the aforementioned media. One of the most significant challenges is in pre-

production, i.e. how quickly a shop can prepare the artwork before it is printed. This is often a limiting factor with regard to more complicated displays and packaging.

So, prior to embarking into 2-D contoured or 3-D graphics, it will be important first to research the corresponding pre-press needs. Graphic design software can be used to set up templates for a variety of sign and packaging formats.

The new pre-press workflow will also need to take post-print finishing into consideration. For the digital cutting required to turn flat graphics into contoured and 3-D products, the shop will need to prepare ‘split’ job files, i.e. with printing information for the printer and cutting information for the cutter. Metadata can also be added such that assembly instructions are printed on the substrate to help the retailer put together a display upon delivery at the store.

There will still always be some workflow changes needed on a project-by-project basis. Overall, however, process engineering can be undertaken for all assets to build a standardized workflow that will make the entire shop more efficient.

Indeed, variations can be derived from the same, shared equipment. By using graphic and design software, pre-production software, printers and cutters together, a shop can produce all of its POP display and promotional packaging applications through a single, complete split-file workflow.

[5]

[5]CNC cutters and routers have made it more economically feasible to produce graphics in complex shapes.

Further considerations

Another important skill is knowing which substrates are best-suited for each job. For POP displays and promotional packaging, relevant materials may include folding cartons, corrugated boards, acrylics, wood, foam boards, fibreglass and metals.

Concurrently, the right tools need to be determined for each substrate and application. This type of work uses a wide variety of oscillating and static knives, tools for partial cutting, milling tools, creasers and bevelled tools.

Finally, a shop will need to build its own design library, indicating which concepts are best-suited for certain types of projects. Shapes and sizes can vary wildly; one way to customize POP displays based on available retail floor space is to take a modular approach.

In other words, wide-format graphics can involve much more than just printing. Shops that focus on high-value projects will experiment with new substrates and build new design-print-cut workflows to maintain their success, growth and profitability. Those that innovate will find the rewards are significant.

| SPREADING THE SUCCESS |

|

The workflow and materials involved in creating 3-D POP displays can yield profound results for brand PSPmarketers. Recently, for example, a food brand marketer turned to digital technology to produce more impactful in-store merchandising displays, leading to a substantial increase in sales of its products. Previously, the brand owner in question had cost-effectively mass-produced 3-D displays by using screenprinting to handle runs that were beyond digital capabilities. However, this arrangement did not allow the sizes of the displays to be changed for different retail environments, such as those where a larger, more eye-catching display could be accommodated. So, the company worked with a PSP to ‘dress up’ its standard POP format by adding new, digitally cut graphics to the sides and headers of its existing displays. It was a simple, modular way to customize them, with merchandising shelves that could be reused or reprinted as needed. Further, by repurposing existing screenprinted displays with new digitally printed graphics, the cost of design and production was not prohibitive for the brand’s marketing budget. The largest structures were rolled out to the top 100 stores selling its products. The results were significant: retailers liked the displays and sales increased by 14.3 per cent compared to the previous quarter. And for the PSP—who provided not only printing and cutting, but also the consultative services that led to the ‘part screen, part digital’ configurations in the first place—the job was extremely profitable. |

Stephen Bennett is vice-president (VP) of sales for Esko in the U.S. central region. This article is based on a seminar he presented at the Specialty Graphic Imaging Association’s (SGIA’s) opportunity zone and theatre at the 2015 Graphics Canada show and follows an earlier piece he wrote for the SGIA Journal. For more information, visit www.esko.com[6], www.sgia.org[7] and www.graphicscanada.com[8].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/07/Esko_Kongsberg-C64_operator.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/07/Design-library.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/07/Value-of-POP1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/07/Value-of-On-Demand1.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2015/07/peeling.jpg

- www.esko.com: http://www.esko.com

- www.sgia.org: http://www.sgia.org

- www.graphicscanada.com: http://www.graphicscanada.com

Source URL: https://www.signmedia.ca/wide-format-printing-maximizing-pop-displays-with-computerized-cutting-and-routing/