Keeping as much colour as possible

There is a common misconception that using a reference space will necessarily limit the capabilities of the printer to the common colour spaces shared by that reference and the printer’s own gamut. This is not always true, however, as there are several strategies that can also be implemented after a file passes through the standardization process:

Spot colour mapping

Spot colours will be mapped to the printer’s gamut and not be limited by the reference output intent. A job using GRACoL as the reference and two Pantone colours, for example, will actually be rendered as a six-channel job, i.e. CMYK plus two spot colours. This method ensures all blending and transparency effects—like drop shadows and overprints—are processed correctly, while enabling the RIP to address the full gamut of the printer.

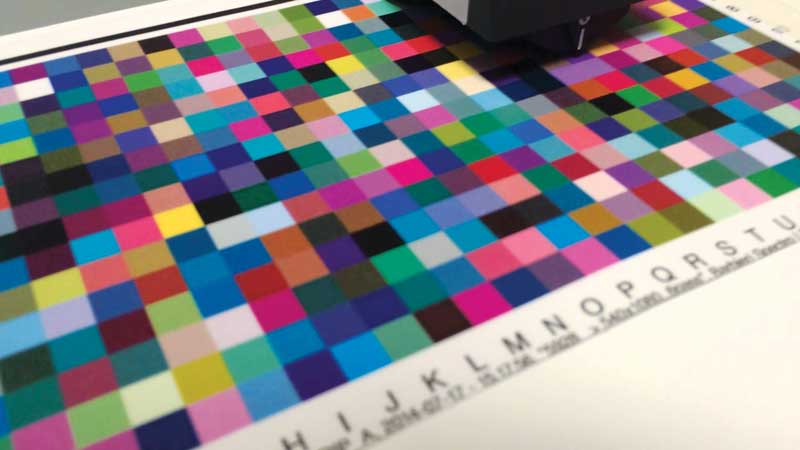

Gamut mapping

The reference colour space—usually CMYK—can be mapped to the printer gamut in any way that is preferred. In some cases, for example, ‘punchy’ colours may be prioritized over printer-to-printer consistency or matching to a contract proof.

If the printer’s gamut is broader than the reference space, then perceptual mapping with black (K) compensation can expand the reference space and maximize the use of the printer’s gamut. If, on the other hand, the printer’s gamut is smaller than the reference space, then a hybrid approach of perceptual and colorimetric mapping is recommended. By keeping the colorimetric mapping within the achievable ‘middle part’ of the gamut and using the perceptual mapping to compress the edges of the gamut, a visually comparable image can be retained without flattening the edge colours.

RGB referencing

For fine art reproductions and photography, an RGB reference space may be used, so as to deliver a broad gamut without separating the image to CMYK, where there could otherwise be breaks in smooth transitions.

After this type of standardization, the image can be mapped to the printer gamut. This way, the image benefits from both standardization and device linking.

A better way

The advantages of standardized printing are significant for the production of wide-format graphics. The key is to choose a RIP that is capable of (a) supporting the standardized printing process for inkjet devices—without the limitations most RIPs face due to their approach to standardizing colour management—and (b) using device-link profiles. The rewards are worth the investment.

Bart Fret is director of large-format sales for GMG Americas, which develops colour management software. For more information, visit www.gmgcolor.com.